Manufacturing Processes

- Casting Technologies (22)

- Die Casting (6)

- Squeeze Casting (1)

- Thixocasting (5)

- Forming Technologies (81)

- Drawing, Deep Drawing and Stamping (24)

- Electromagnetic Forming (6)

- Extrusion (2)

- Forging (2)

- Hydroforming (19)

- Super Plastic Forming (SPF) (4)

- Tailor Welded Blanks (TWB) (11)

- Joining Technologies (27)

- Arc Welding (4)

- Friction Stir Welding (6)

- Laser Welding (3)

- Resistance Spot Welding (RSW) (1)

- Rivets (2)

- Structural Adhesives (5)

- Welding (1)

- Other Technologies (2)

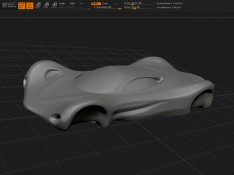

- Rapid Prototyping (58)

The Secret World of Printing Concept Cars in 3-D

The work that goes into building a physical model of a concept car is usually hidden behind closed doors, known only to engineers sworn to secrecy and similarly tight-lipped subcontractors. Ask anyone involved exactly which companies use 3-D printing technology to create concepts and the answer will invariably be, “many of them.” One company, however, […]

Resistance Spot Weldability of High Strength Steel (HSS) Sheets for Automobiles

Resistance spot welding technologies of high strength steel (HSS) sheets were investigated in order to get high reliability in welded-joints of automobile components. Suitable welding current range shifted to lower currant side by the effect of electric resistance increase of steel sheet and the width of this range was affected by electrode force. Vickers hardness […]

Hydroforming High Strength Steel Tube for Automotive Structural Applications

The need for lighter, stronger, more rigid vehicle structures will increasingly require complex hydroformed structural tubes to increase strength, and decrease weight, cost and part count. This effort will increase the use of high strength, low alloy (HSLA) steel, in place of SAE 1006/1008 or 1010 steel. Traditional hydroforming techniques require the higher elongation of […]

Introduction to the Hydroforming Processes

To try to answer some of the most important global demands of current designs, such as economic efficiency of technical solutions, careful handling of energy and raw materials, optimized work-piece properties innovations in processes and approaches, near to more conventional solutions, are developed. Moreover it is to consider that the increasing technological demands concerning the […]

Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys

Magnesium-aluminium castings produced by means of squeeze casting, new rheocasting and thixocasting have been investigated. These casting processes provide very different microstructures consisting of a-Mg and b-Mg17Al12. The shape and distribution of the brittle b-Mg17Al12 has a large influence on mechanical properties. Isolated particles of b-phase in squeeze cast components are less detrimental to ductility […]

Optimization of a Tube Hydroforming Process

An approach is presented to optimize a tube hydroforming process using a Genetic Algorithm (GA) search method. The goal of the study is to maximize formability by identifying the optimal internal hydraulic pressure and feed rate while satisfying the forming limit diagram (FLD). The optimization software HEEDS is used in combination with the nonlinear structural […]