Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys

Abstract/Summary

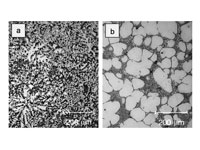

Magnesium-aluminium castings produced by means of squeeze casting, new rheocasting and thixocasting have been investigated. These casting processes provide very different microstructures consisting of a-Mg and b-Mg17Al12.

The shape and distribution of the brittle b-Mg17Al12 has a large influence on mechanical properties. Isolated particles of b-phase in squeeze cast components are less detrimental to ductility than the continuous b-phase network found in semi-solid processed parts.

A heat treatment results in complete dissolution of b-Mg17Al12 and accounts for significant improvements of ductility and fracture toughness. Crack propagation in solution heat treated Mg–Al castings is associated with extensive twinning.

share on Buffer

share on Buffer