Quantitative Characterization of Near-Field Fuel Sprays by Multi-Orifice Direct Injection Using Ultrafast X-Tomography Technique

Abstract/Summary

A low-pressure direct injection fuel system for spark ignition direct injection engines engines has been developed, in which a high-turbulence nozzle technology was employed to achieve fine fuel droplet size at a low injection pressure around 2 MPa. It is particularly important to study spray characteristics in the nearnozzle region due to the immediate liquid breakup at the nozzle exit.

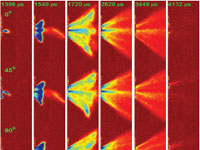

By using an ultrafast x-ray area detector and intense synchrotron x-ray beams, the interior structure and dynamics of the direct injection gasoline sprays from a multi-orifice turbulence-assisted nozzle were elucidated for the first time in a highly quantitative manner with μs-temporal resolution.

Revealed by a newly developed, ultrafast computed x-microtomography technique, many detailed features associated with the transient liquid flows are readily observable in the reconstructed spray. Furthermore, an accurate 3-dimensional fuel density distribution, in the form of fuel volume fraction, was obtained by the time-resolved computed tomography.

The time-dependent fuel density distribution revealed that the fuel jet is well broken up immediately at the nozzle exits.

These results not only reveal the near-field characteristics of the partial atomized fuel sprays with unprecedented detail, but also facilitate the development of an advanced multi-orifice direct injector. This ultrafast tomography capability also will facilitate the realistic computational fluid dynamic simulations in highly transient and multiphase fuel spray systems.

(Source: Gruner Group - Cornell University)

share on Buffer

share on Buffer